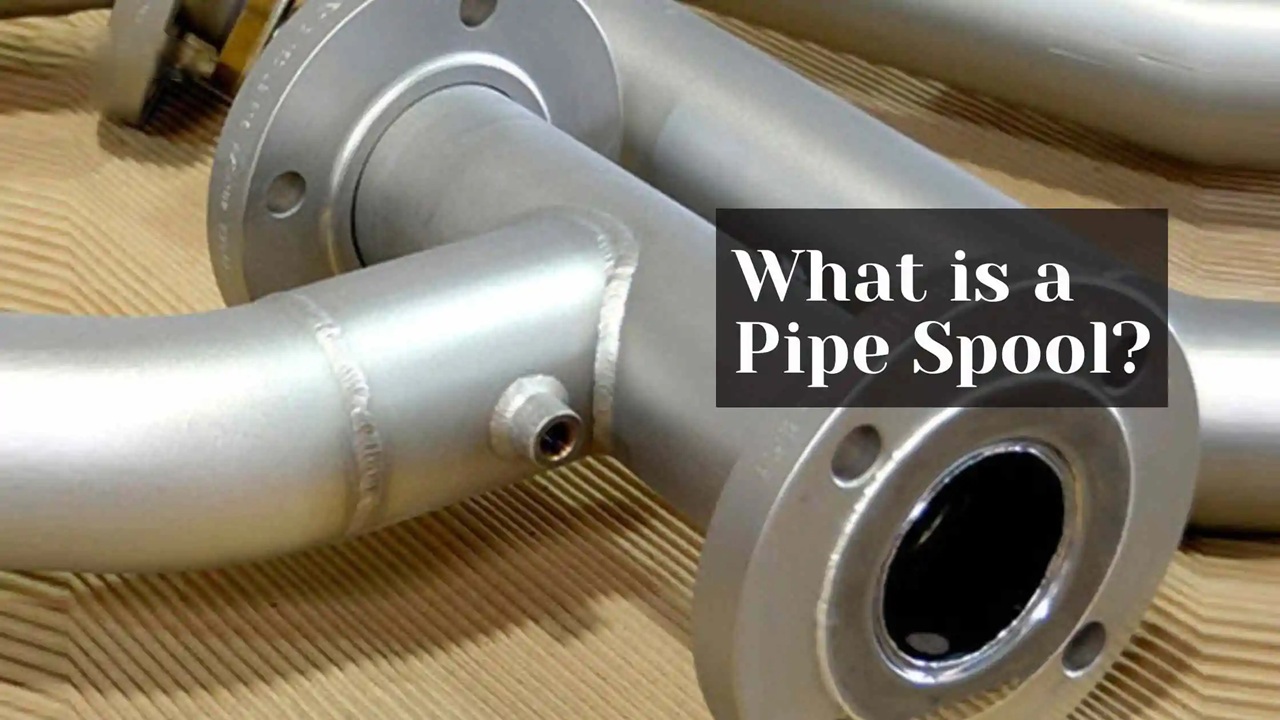

Workshops produce pipe spools, which become ready industrial pipes that go to buildings and factories. These components belong to an extensive pipe system that transports fluids, gaseous materials, or air. Pipes and flanges, as well as elbows, serve as components that compose the spool assembly. Different components receive their shape through cutting, followed by a joining operation, before welding completes the process. The workshop provides safer and faster pipe spool production than conducting the entire process at construction sites. The production process finishes when the spools get transported to the job site for further connecting to other spools. Factory pipelines, together with power plant installations and large facilities, benefit from faster construction due to pipe spools by Tuspipe. The installation of spools ensures both work cleanliness and orderly organization. This article provides information on What is a Pipe Spool- Flange Pipe Spool/ Spool Pieces.

What Are Pipe Spools Made Of?

Various materials serve as the basis for manufacturing pipe spools. The selection of material base depends on two factors: which substances the pipe should transport, and its intended installation location. Manufacturers produce spools with carbon steel and stainless steel since these metals offer high strength. Such materials function well when required to grasp both hot substances and heavy loads or dangerous objects. Some pipe spools employ plastic components as well as lightweight metals whenever the application requires minimal toughness. A complete pipe spool contains its main components, such as pipes and elbows, together with tees, flanges, and valves. Welding combines the pieces with additional bolting used to form the interconnections. Every section contains its designated role, which includes bending the pipe as well as connecting two pipes and adding closure whenever necessary. Every spool is made to fit a plan, so everything connects the right way.

How Are Pipe Spools Made?

Making a pipe spool takes careful work. It starts with a drawing or plan that shows the size and shape of the spool. This plan also shows where the pipe needs to turn, where the flanges go, and how long the pipe must be. First, workers cut the pipes to the right length. Workers begin to attach elbows alongside flanges and various parts to the pipes that follow. The welders or bolters unite the assembled pipe parts after fitting them onto the pipes. The entire process receives multiple inspections to guarantee proper completion at every stage. At the completion of each spool, its cleaning process begins, followed by painting and, if necessary, testing for integrity and leak security. The completed spools proceed to their destination at the construction area. Additional spools are joined to each other by workers to construct complete pipeline systems. On-site installation takes much less time than building everything at the job site.

Where Are Pipe Spools Used?

Different locations require the use of pipe spools. Managerial personnel frequently deploy pipe spools within both factories as well as power plants and oil refineries. Stable and secure pipe systems that transport water, gas, oil, and chemical substances must be installed in these locations. Spools help build these systems quickly and safely. Spools are also used in tall buildings, hospitals, and schools. These places need pipes for water, air, and sometimes special gases. Workshops that produce spools help maintain clean facilities while delivering proper pipe connections in their first installation attempt. Pipe spools serve applications in all locations that utilize pipes. These items serve three useful functions by reducing work duration, simplifying operations, and maintaining safety conditions.

Why Are Pipe Spools Important?

Pipe spools are important because they help people build strong, safe, and neat pipe systems. If workers tried to build all the pipes on-site, it would take too long, cost more money, and be harder to do right. When spools are made in a workshop, workers can take their time and use the right tools. They can measure carefully and make good, clean welds. The spools can also be tested before they go to the job site, which makes it safer. By using spools, the job moves faster.

How Tuspipe Handles Pipe Spools

Tuspipe makes pipe spools for many different projects. The company follows clear plans and uses good materials for every job. First, the workers at Tuspipe check the plan to see what the spool needs. Then, they cut, weld, and put together the parts. Each spool is checked to make sure it is made the right way. Some spools are painted or cleaned to protect them. Others are tested with water or air to check for leaks. When the spools pass all the checks, they are packed and sent to the job site. Tuspipe takes care to follow the plan so everything fits well and works safely when it is installed.

Conclusion

A pipe spool is a ready-made pipe section built in a workshop. It is made of pipes, elbows, flanges, and other parts. Spools are made to fit together at a job site to build a full pipe system. It also keeps the work clean and helps avoid mistakes. Tuspipe makes strong, safe spools by carefully following plans, using good materials, and testing the spools before they are sent out. This way, every pipe system is built the right way, ready to work when needed.